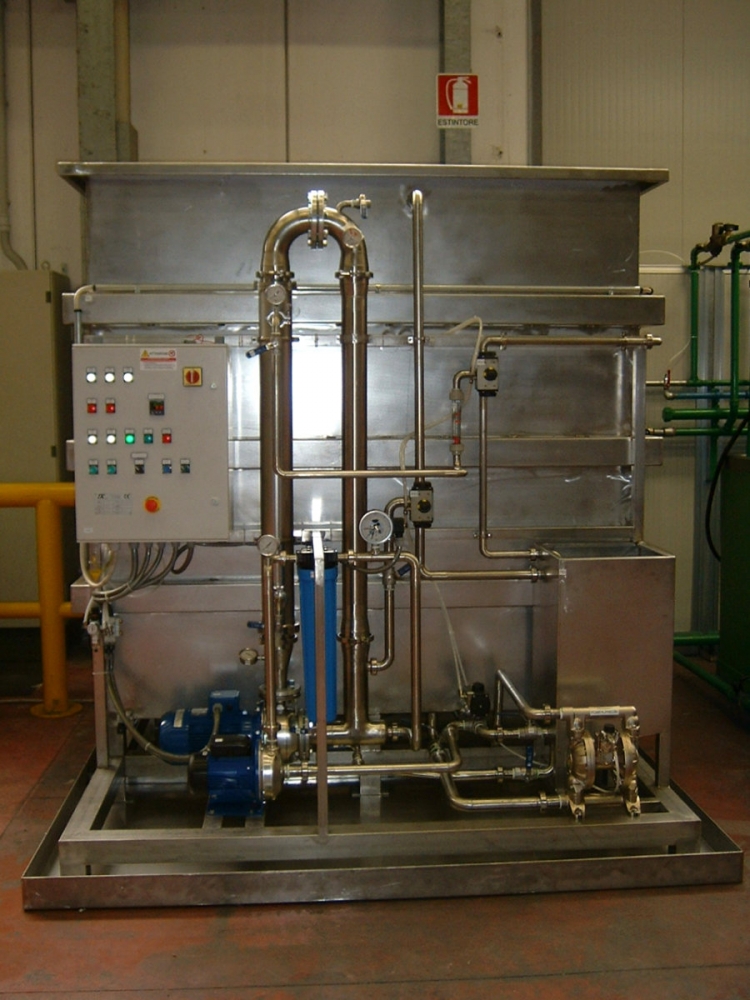

Ultrafiltration machines for gold recovery

Ultrafiltration machines for gold recovery

Recovery of precious metals

The recovery of precious metals from spent solutions deriving from various production processes is a considerable source of income with low operational costs.

For the recovery of precious metals from spent solutions, treatment in ultrafiltration (UF) plants is definitely the simplest, fastest and most profitable technique.

The procedure consists in collecting and transferring to a tank the solution containing micro-particles of precious metals deriving from:

- hand-washing units;

- ultrasonic washing machines;

- tumblers.

From this point the solution is collected, pre-filtered and sent to the ultrafiltration plant. The concentrate containing the metal is dried by means of an evaporator and transferred to the metal recovery unit.

The purified water can be discharged, eventually prior to activated carbon treatment.

The main advantages of this system are:

- rapid return on investment;

- high selectivity in the individual recovery of metals;

- recovery with degrees of purity of metals up to 98%;

- the recovered metal can be easily sold;

- high-quality components ensure resistance to aggressive liquids;

- minimal maintenance.

Discover all other products:

We study the most suitable solution for your company.