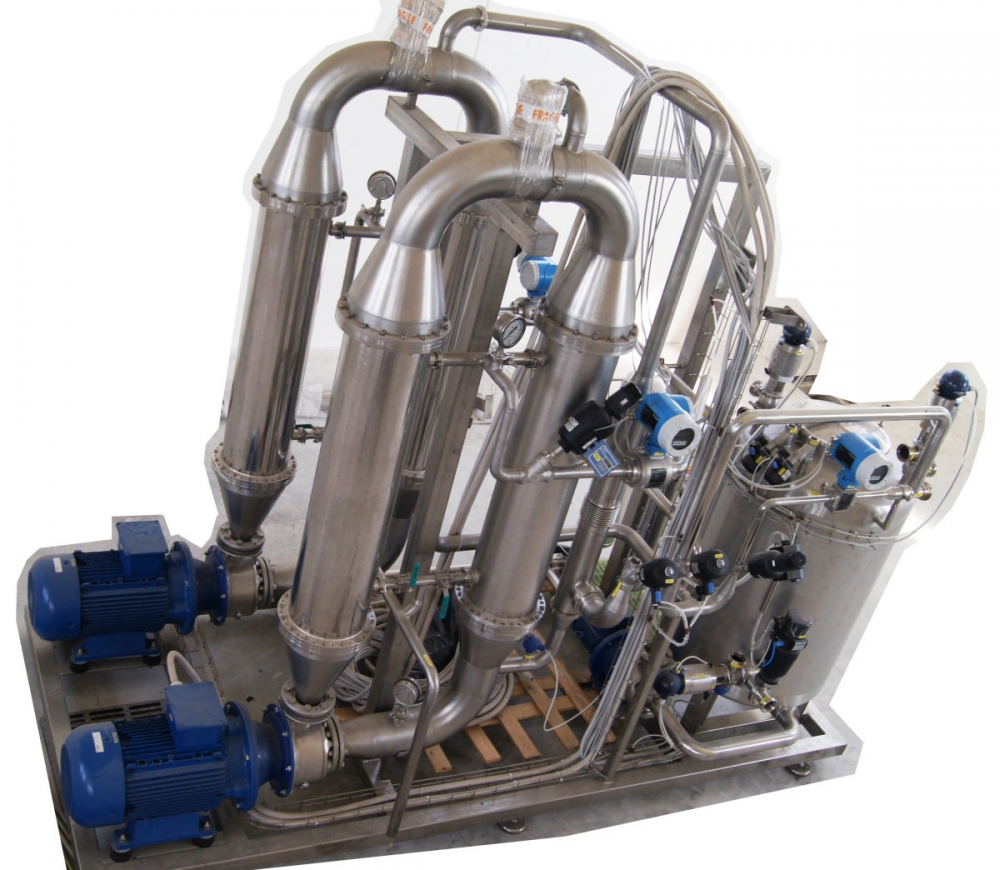

Microfiltration for milk debacterization

Milk treatment process

Membrane separation based milk treatment technology is becoming increasingly important on account of its peculiar characteristics. In particular, it allows for low temperature processing, which preserves the highest level of quality of the milk, avoiding the degradation of "noble" proteins.

The well-established processes are:

- concentration of milk up to five times prior to cheese-making;

- standardization of milk to obtain uniform protein content prior to cheese-making;

- cold-debacterization of milk, avoiding the denaturation of proteins induced by the heat treatment of pasteurization.

The standardization and concentration processes can be achieved with sanitary grade polymeric and ceramic membranes.

Cold debacterization is obtained with particular tubular ceramic membranes, having a molecular weight cut-off of 1.2 - 1.4 micron, called ISOFLUX because of their peculiar characteristic of maintaining a constant transmembrane pressure along the channel; they provide a 5-6 log reduction of the bacterial load typical of milk.

Membrane application tool

In the above mentioned field of process technologies, TA is able to provide full support in what regards the application of both polymeric and ceramic membranes.

Discover all other products:

We study the most suitable solution for your company.