Plants for the treatment and reuse of processing liquids

Plants for the treatment and reuse of processing liquids

Process solutions are nowadays fully considered as an integral part of the production line. Process liquids, which were once seen only as waste and a problem to be dealt with, often implying costly purification treatments, are now much more manageable thanks to modern technologies which provide simple and customised solutions.

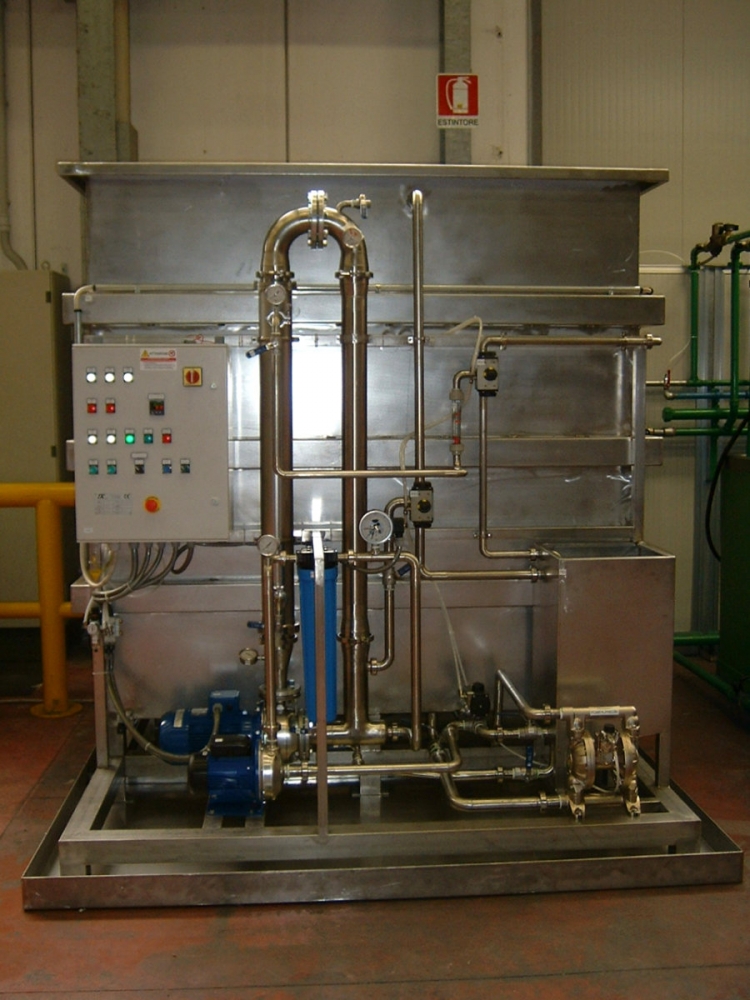

The technologies offered by T.A.srl have become increasingly attractive to the industry, partly due to the fact that we are able to customise the machinery for any specific need. In the most complex cases we offer trials with pilot plants to test the functioning and efficiency of the process.

We are always available, along with our technicians specialised in the treatment and reusage of process liquids, to evaluate and treat each individual case.

T.A. Applied Technologies for process solutions: applications

We offer the best ultrafiltration (UF) machinery for oil recovery because we know that water-oil emulsions are considerably present in industries, concerning both metal and surface works. These emulsions are unfortunately prone to pollution and must therefore be disposed of as hazardous waste, as well as constantly needing to be substituted.

T.A.srl offers plant setups that combine oil removal to ultrafiltration machines, such as to separate the oil that can then be delivered to the Consorzio Recupero Oli, and obtain water that can be reused in the production cycle. This will avoid wastes and environmental impact, as well as cutting times and costs of industrial workings.

We deal with planning of ultrafiltration plants for the recovery of gold from exhaust solutions connected to various production processes. Thanks to this process solution it is possible to significantly increase profit within reasonable management costs and times.

The procedure that we suggest consists in collecting and sending to a deposit the solution containing metallic microparticles (recovery of metals, up to 98% purity) which can then be recovered by incineration of the concentrated solution.

We also offer innovative ultrafiltration plants for the recovery of surface washing waters. At the end of the process it is then possible to recover high quality, salt free water to be used in the production cycle as washing water.

Our ultrafiltration machines for graphics treat waste solutions containing oils and fats, traces of hydrocarbons and metals. We apply this treatment with the aim of reducing waste volumes in order to render its disposal easier and cheaper. Reverse osmosis technologies are also used for the functioning of galvanic rinsing treatment, used especially in deposition baths or for various plastics and electric component workings.

T.A.srl realises ultrafiltration machines with ceramic membranes for the recovery of flexographic solvents. This solution consists of a pneumatic functioning system, ideal for applications in absence of an electrical current, thus suitable for washings with a solvent or water and a detergent without the risk of a short circuit or fire. Ceramic filtration membranes are used because they resist chemical attack from any industrial solvent.

We rely on 30 years of experience, we support industries in renewal and modernisation of plants, in respect of rules and regulations and suggest new environmentally friendly solutions.

Discover all our applications and designs for the treatment and reuse of process liquids:

We study the most suitable solution for your company.